I think nearly every soapmaker makes a mistake and winds up with lye-heavy soap. I unmolded these beauties this morning. This soap was supposed to be a really nice lavender goat milk soap. I’m not happy that I used some nice materials with this result, but it does happen.

I unmolded these beauties this morning. This soap was supposed to be a really nice lavender goat milk soap. I’m not happy that I used some nice materials with this result, but it does happen.

I knew something was wrong as I was mixing this soap together. It seemed to trace much more quickly than I thought it would, and I wondered if it was false trace, so I kept blending. I am still not sure if it really did get mixed well.

I check on my soap frequently as it sits to gel, and this one acted up almost immediately. I could see a yellow fluid oozing out of the tops of the bars. And it kept oozing, even after I patted it dry with paper towels. I checked it several more times, and each time, more liquid ooze.

It also seemed to take quite a long time to begin to gel. A few hours passed before I detected the temperature was over 100°F. It also seemed softer than usual. Even if soaps haven’t yet begun to gel, they begin to harden so that you can press lightly on the surface.

Sure enough, when I unmolded the soaps this morning, there was a large amount of that yellow liquid underneath the bars. They were the mottled shade you see in the image rather than a nice uniform lavender shade. I could see the lye much better on the bottoms of the bars, so out of curiosity, I put a pH strip into some of the oozy liquid on the bottom of a bar.

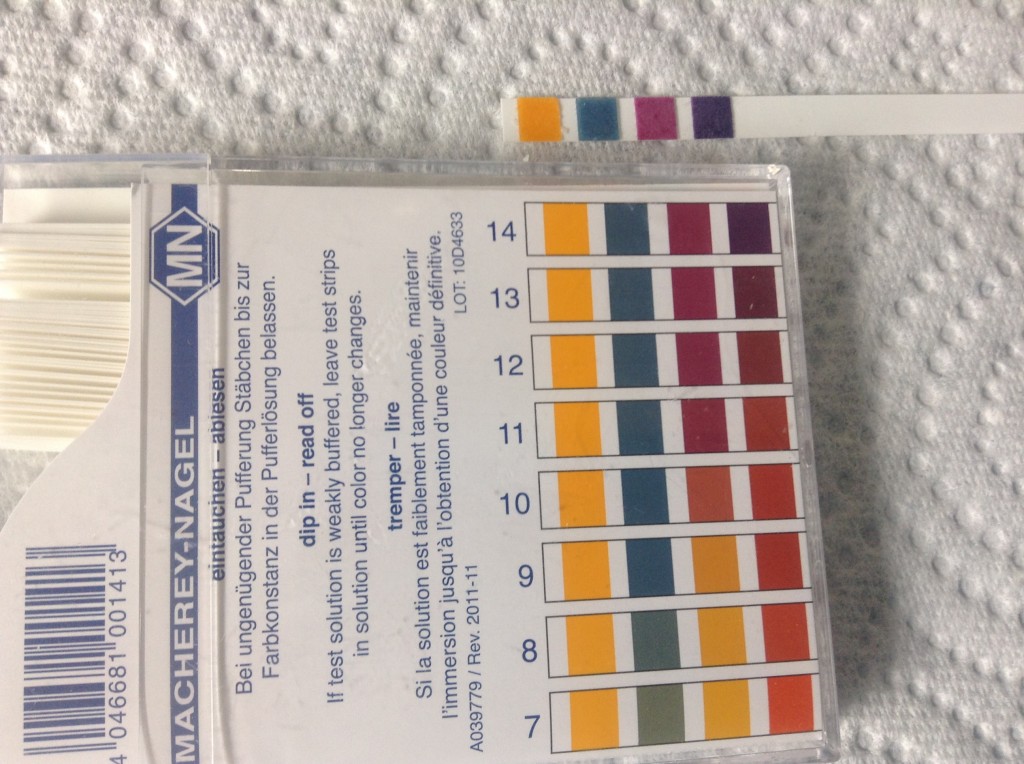

If you haven’t used these kinds of test strips before, you might not be familiar with how to read them. Essentially, you hold the strip up to the scale on the package above and compare it to the different sets of colors. I think my test strip looks most like the set labeled 14. If you are not familiar with the pH scale, it works like this:

If you haven’t used these kinds of test strips before, you might not be familiar with how to read them. Essentially, you hold the strip up to the scale on the package above and compare it to the different sets of colors. I think my test strip looks most like the set labeled 14. If you are not familiar with the pH scale, it works like this:

- It ranges from 0-14.

- It measures how acidic or basic (or alkaline) a substance is.

- Substances with a pH below 7 are acidic.

- Substances with a pH above 7 are alkaline.

- Substances with a pH of 7 are neutral and are neither acidic nor alkaline.

- Each number is ten times greater than the number before. For example, something that is pH 11 is ten times more alkaline than something that is pH 10. Likewise, something that is pH 4 is ten times more acidic than something that is pH 5.

- 14 is just about as alkaline as you can get. Lye is about 14 on the pH scale.

Yikes! I certainly should not have been handling my soap with bare hands! It was dangerously lye heavy. I immediately washed my hands. The tips of my fingers are a little dry, but other than that, no damage. A quick note: The soap itself was probably not uniformly pH 14. I’m pretty sure the pH strip came in direct contact with a patch of lye in the soap. In any case, I should have been using gloves to unmold. I’m really glad I didn’t try to zap test it.

In the case of this particular batch, I don’t know what I did wrong, so rebatching it in an attempt to fix it is probably not a good idea. If you know exactly what you did wrong to produce lye heavy soap, you can try rebatching it and correcting the problem. For instance, if you know you forgot an oil, or that you used the wrong amount of oil, you can shred the soap with a grater and put it in the crock pot, add the oil, and cook the soap, similar to making hot process soap. I personally hate rebatching. Your rebatched soap is just not going to be as nice as regular cold process or even hot process soap. I have done it once and swore I’d never do it again. However, some soapmakers regularly rebatch their soap and like it just fine.

What can you do if you don’t know what you did wrong? You have two options:

- Toss it in the trash.

- Use it as laundry soap.

I put on a pair of gloves and shredded the soap. Then I put it in a box in the laundry room. Interestingly enough, the first soaps used were laundry soaps. Ancient Babylonians used soap as early as 2800 BCE. Archaeologists have found evidence of a soap-like residue in containers, and a cuneiform tablet dated from 2200 BCE had a soap recipe on it. The recipe describes the soap’s use for washing clothes. Your grandmother or great-grandmother may even have made soap to use for the laundry. Though lye-heavy soap is too harsh to use on your skin, you can use it to clean your clothes, and that way, at least it doesn’t go to waste. Lye-heavy soap is actually pretty good at whitening whites and cutting grease. It’s best used with some washing soda, Borax, and baking soda to create a nice detergent. The Soap Queen has some laundry soap tips here.

Lye heavy soap happens to all of us =) Laundry soap is a great choice for it.

I haven't had a batch like this in a while, and it's the first time I didn't figure out what I did wrong. I still don't know! The second batch I made turned out great.

I just had my first lye-heavy batch of soap and came across your site searching for a way to rebatch it. When I was making it, it started to trace and then it seemed to get thinner. I must have had a false trace, but I’ve never experienced that before. It sounds exactly as you describe; when I unmolded it, there was yellow oily fluid oozing, which I assume was unsaponified oils.

I have to say it works really well as laundry soap. I still really don't know what I did to cause the problem. I suspect a measuring mishap. I hope you were able to figure out how to rebatch yours.

hi I did a big mistake, I forgot to add my 10% rice bran oil. my soap turn out perfect but heavy lye. can I rebatch my soap in croock put? I just add 100 grm of rice bran oil and 100 grm of water. and I add activated charcoal? bcz the soap has lovely smell. but after rebatching how many weeks I have to cure my soap?

please reply to me. thanks

Sherry

Since you know exactly what you did, yes, you should be able to rebatch your soap in the crock pot, shredding your lye-heavy soap and adding the 10% rice bran oil and some more water for cooking out. You can add anything else you’d like. In my personal experience, colors don’t disperse as well in hot process soap. Rebatched soap doesn’t need a long cure because you cook it. You can actually use it within a few days. Many soapers recommend waiting a couple of weeks anyway, but you don’t have to.

i have experience with lye heavy too. but i didnt know where i was wrong. the soaps was crumbly, crack, with yellow and white dots are everywhere. i hate rebatching too lol

Wow. Great info. Thank you so much… i made my soap 12 hours ago. Unmolded it and cut. Noticed that my cut bars started to sweat… i too did a boo boo and didnt wear gloves. Notice my fingers started tingling. Quickly washed my hands. Used a ph strip and it reached 14 on scale. Is it possible that after 4 weeks this ph level will decrease? How much ph is soap suppose to be after the day you made it? Such beautiful soap but im worried now that maybe the ph level wont decrease over curing time…

Veronica, it should be milder over time. If you test it after a week, and it’s still high, it could be lye-heavy, but usually soapmakers cure their soap for at least four weeks.

Help! I made coconut oil soap using a crockpot. The crockpot kept shutting off for some reason (I’m a newbie, and so is the crockpot which has been returned!), so I put it all in a double boiler, and tried to reheat and cook it. It went through a cottage cheese stage and then a mashed potato stage, and finally I gave up after 4 hours, and mushed it into the pan.

After 24 hours, it is totally crumbly, has wet spots and does not act like soap at all. It burns my fingers. What can I do?

I suspect that it didn’t fully saponify. You can try cooking it to see if that works, but it might not. This might be a ruined batch. I have had a few of those. Been there! It’s frustrating, but it is part of learning how to make soap.

I unmolded my goatsmilk soap after an overnight in molds…they looked and smelled lovely BUT they are crumbling..i forgot to double my oils so they are lye heavy..i threw them in a crock and added olive oil and shea butter..its quite liquidy, hoping this will work for a rebatching. How long do you think i should keep in crock?

Thanks!

Katy, I’m probably too late to help you here, but I hope you found the answer online from a rebatcher or hot process soap maker. I have little experience with either one. After a while, I have noticed the soap is thick and looks, well, soapy, and that’s how I’ve gauged it in the past. You did the right thing, though. It definitely sounds like they were lye heavy.

Hello Dana,

I’ve been researching this but so far I can’t find out and ended up here in your nice post.

If you want a lye heavy soap for especific cleanings (stove, greasy floor etc)? Have you tried or experienced some?

Once made, for sure it would have to be handled with protection (gloves for sure) but I’m wondering how it could work for these cleaning purposes.

I tried to calculate superfatting at -1% and -2% on soapcal.com and it does calculate! I wouldn’t make a soap with more lye than that anyway.

Sorry for my rusty English.

Best regards!

Rodrigo, that is an interesting idea and one I have not tried. I assume you are right that it would need to be handled carefully. I have heard of folks using lye-heavy soap to make laundry detergent, so I don’t see why your idea wouldn’t work as long as you are very careful with it. You might also patch test it to make sure it doesn’t ruin the surfaces you are trying to clean.

I purposely make lye heavy soap for the sole purpose of making laundry soap. I leave it about 1-2% lye heavy. Not sure exactly how lye heavy I can make it so I just stick with that percentage. I also only use coconut oil because coconut oil produces a highly cleansing bar which is great for cutting through grease. The extra lye binds to any oils/grease in the clothes and essentially create more soap as it goes through the wash cycle!

I made cold process soap. Its my second time making soap. The oils, lye were all accurately weighed. Lye was warm but I forgot to keep the oils in a warm temperature when mixing with lye. Lye was at 95F but forgot to check on oil temp with the distaractions at home. SO my trace reached in almost seconds and was too thick to even pour into mold. Yet I did blend it for may be 20 more seconds. Its been 2 weeks since I made it. I tried zap test and didnt feel a thing. I and my husband tried couple times but it didnt zap. Suggest me how to rebatch it? Can I do it by heating in oven? I would like to make a skin soap rather than a laundry soap out of it. I removed the soap after 2 weeks and just now chopped into 1 inch slices. It was sticky and sticking to the soap knife I had to slide it out

I’d suggest using a crock pot to rebatch.

I made a CP soap with olive, coconut, and caster oil as well as about 25% tallow. It was a larger batch than I usually make. When I poured the lye in the oils the handle slipped and all of it went in at once. I stirred it and then hit it with the stick blender. It seemed really goopy and thick at the bottom but after a few seconds it started acting like normal soap. I put my scent in (usually non accelerating) and poured it into my various containers to be colored. As I was mixing the colors in I noticed it starting to thicken up quite quickly so I poured it into the molds and did my swirling. I wrapped it in a big towel and set it aside. I wasn’t able to get back to it until about 28 hours later. It was beautiful, popped right out of the molds but was super hard. When I tried cutting it with my usual knife it split and cracked with lots of pieces. It seemed to follow the color lines. I tried a couple of different ways (no professional cutter) and finally got out my dental floss, wrapped it around a couple of spoon handles and got it cut. There is no oozing, it doesn’t feel dry but there is a bit of what I thought was ash (hubby said it got very hot during the towel time). It doesn’t zap my tongue and after a week, if I wash with it, I don’t feel like it is “burning”. I don’t think I left any oils out and I ran the recipe through the SoapCalc test. Could the tallow have made it hard that quickly and be causing the brittleness? It is hard like a regular, shinny commercial soap and I can break the bar half. What options do you think I have? It turned out beautiful (of course) and I would be happy to rebatch if it might work.

I think tallow accelerates trace and contributes to a harder bar, so it could be the tallow. I haven’t worked with tallow, so I can’t really say how it behaves. Do you have ph strips to test whether the soap is too alkaline or not? Rebatching it could always work, but I might try testing the ph to see if it’s fine to use as is. If it didn’t “zap,” it is probably okay, but my guess is that the oils and lye/water didn’t blend as much as they needed to, given the accident.